PEEK Monofilaments is the abbreviation for polyetheretherketone, which is a high-performance thermoplastic engineering plastic.

PEEK has excellent mechanical properties, such as high strength, high stiffness, and good wear resistance; It has high temperature resistance and can be used for a long time at a high temperature of 260 ℃; Has excellent chemical stability and can resist the erosion of various chemical substances; It also has good electrical insulation and flame retardancy. Due to these excellent properties, PEEK has a wide range of applications in aerospace, automotive, electronics, medical and other fields.

PEEK is a high-performance variety of polyaryletherketone polymers and is currently one of the most comprehensive thermoplastic polymers. The types of PEEK products are very diverse, mainly classified into injection molded finished parts, continuous extruded sheet/rod profiles, as well as films, capillaries, and other products.

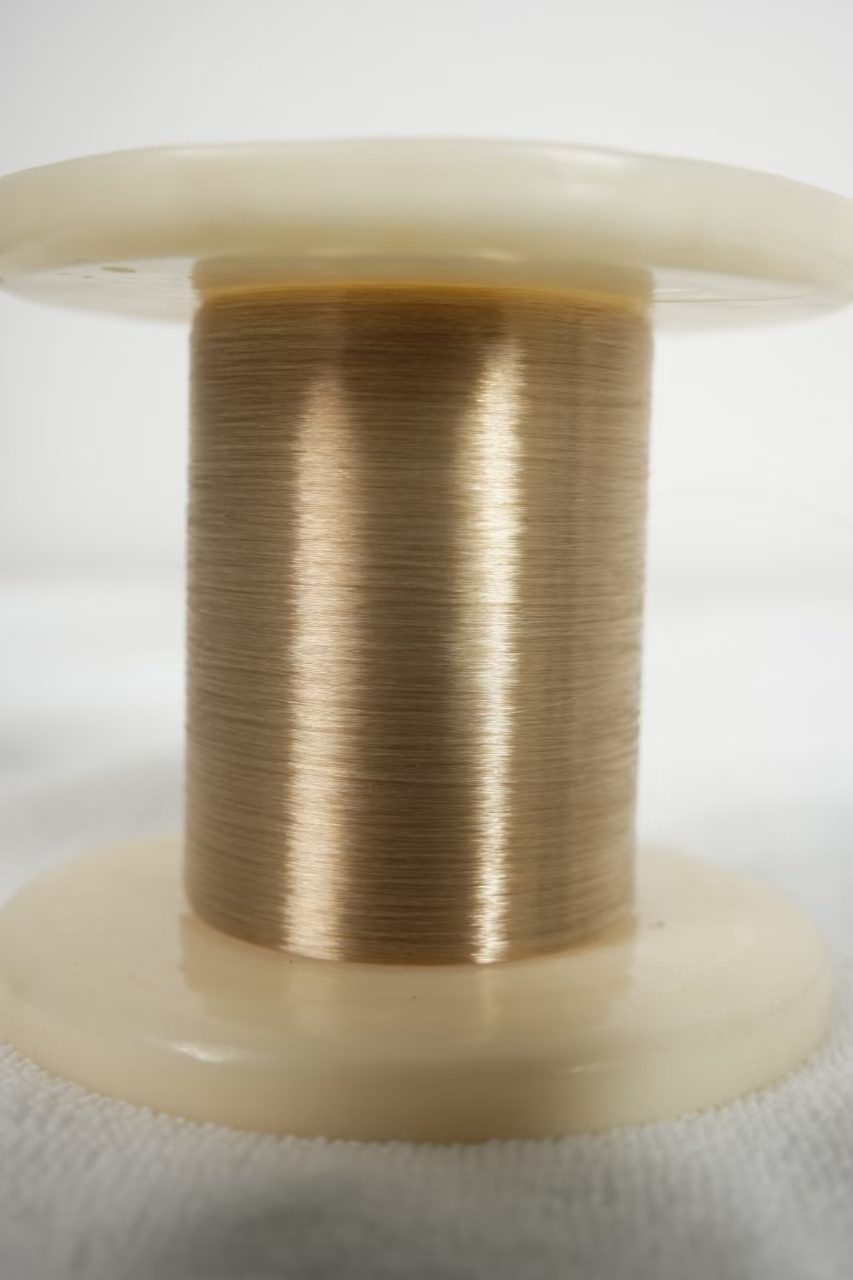

Our company has developed various sizes and specifications of PEEK monofilaments (fibers) according to customer needs. PEEK filaments have excellent insulation properties, outstanding strength, and excellent heat and chemical resistance.

Performance of PEEK monofilament (fiber)

PEEK (polyetheretherketone) monofilament (fiber) has excellent properties. Tensile strength of 600-700MPa (single filament fracture strength of about 50 cN/tex), elongation of 40%, melting point of 340 ℃, weight of 430 g/10000 m (diameter 0.2 mm).

PEEK monofilament (fiber) application fields

PEEK monofilament (fiber) has the characteristics of steam resistance, wear resistance, creep resistance, good toughness, and good biocompatibility. It is widely used in dry canvas, heat-resistant filter cloth, tennis racket mesh, composite materials (mixed with CF, GF, etc.), fuel filter screens, artificial ligaments, and high-temperature insulation sheaths on airplanes in paper making machinery.