Causes of Fuzz Filaments in Polyester Monofilaments

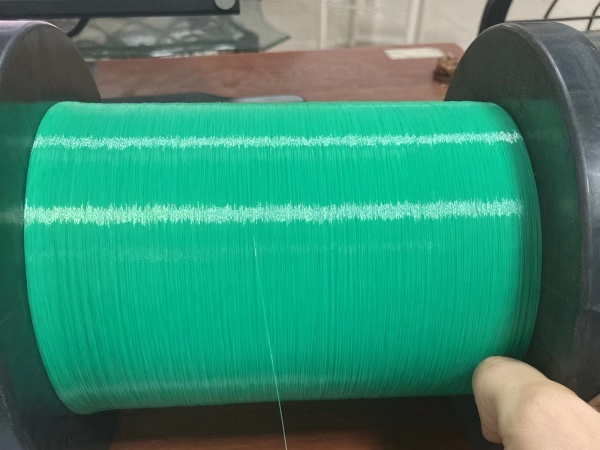

As a crucial variety of synthetic fibers, polyester monofilaments are widely used in the textile industry. However, the issue of fuzz filaments has long plagued the production and quality improvement of polyester monofilaments. Fuzz filaments not only affect the appearance and hand feel of fabrics but also may lead to problems such as yarn breakage and weaving defects during subsequent processing, reducing production efficiency and product quality.

I. Causes of Fuzz Filaments

(I) Equipment Factors

1.Mechanical Wear: During the production of polyester monofilaments, the filament yarn passes through multiple yarn-guiding components, such as thread guides and oil nozzles. After long-term use, the surfaces of these components may become worn, scratched, or rough. When the filament yarn comes into contact with these worn parts, it is prone to abrasion, resulting in damage to the fiber surface and the formation of fuzz filaments. For instance, if a thread guide has insufficient material hardness or poor surface treatment, it will quickly wear out under the repeated friction of high-speed running filament yarn, thereby affecting the yarn quality.

2.Uneven Tension: If the tension control system on the production equipment malfunctions or is improperly adjusted, the tension applied to the filament yarn during operation will be inconsistent. When the local tension is excessively high, the filament yarn will be overstretched, damaging the internal structure of the fiber, and the surface fibers are likely to break, forming fuzz filaments. Conversely, if the tension is too low, the filament yarn may become loose and entangled with each other, which also tends to cause fuzz filaments during subsequent processing.

(II) Process Factors

1.Spinning Temperature: Spinning temperature has a significant impact on the quality of polyester monofilaments. Excessively high temperatures reduce the viscosity of the polymer melt and enhance its fluidity, which may cause the filament yarn to have uneven thickness and an unsmooth surface when extruded, easily leading to fuzz filaments. On the other hand, excessively low temperatures result in poor melt fluidity and increased spinning pressure, making it difficult to extrude the filament yarn. This may cause melt fracture, which also degrades the surface quality of the filament yarn and triggers the problem of fuzz filaments.

2.Winding Speed: The matching degree between winding speed and spinning speed is crucial. When the winding speed is too fast, exceeding the stretch capacity of the filament yarn, the yarn will be overstretched, leading to excessive orientation of molecular chains inside the fiber. This reduces the fiber strength, and the surface fibers are prone to breakage, forming fuzz filaments. If the winding speed is too slow, the filament yarn stays in the air for too long and becomes brittle due to overcooling, which also easily results in fuzz filaments.

(III) Material Factors

1.Chip Quality: Poor quality of polyester chips used in polyester production directly affects the quality of filaments. If the intrinsic viscosity of the chips is too low, the melt strength during spinning will be insufficient, making the filament yarn prone to breakage and fuzz filaments. Excessively high impurity content in the chips, such as metal ions and dust, will become stress concentration points during spinning, causing the fiber to break at these points and form fuzz filaments.

2.Oil Agent Performance: Oiling is a critical link in the production of polyester monofilaments, and the performance of the oil agent has a significant impact on the formation of fuzz filaments. If the oil agent has poor lubricating performance, it cannot effectively reduce the friction between the filament yarn and equipment components, making the yarn prone to abrasion and fuzz filaments. Insufficient antistatic performance of the oil agent will cause static electricity accumulation on the yarn surface, leading to yarn entanglement and dust adsorption, which in turn triggers the problem of fuzz filaments.